The installation of plastic windows is not easy in itself, but it is even more difficult to install a window in a wooden house. The tree is always subject to shrinkage. Of course, the blockhouse is "kept" in order to get rid of excess moisture, but this process continues for at least five years, and in some regions, the entire service life of the house. In this case, the height of the wall can decrease by a centimeter and a half per meter of masonry, i.e. up to 6 cm.

So that the logs do not press on the window when drying out, a special design is used during installation, the so-called shedding, or jamb. The shrinkage prevents the logs from deviating from the vertical line and takes over the entire load. If the casing is not made, then as the logs dry out and their diameter decreases, it will become more difficult to open and close the window. Today we will consider the main types of mugs in a wooden house, the most preferable for the installation of plastic windows.

5. Types of casing and casing by design

First you need to decide what material to make the casing from. The cheapest option is typesetting-adhesive, made of edged material, fastened with microthips and moisture-resistant glue. The combined window will be slightly more expensive, where the upper and side parts are made of solid pine, and the threshold is type-setting and adhesive. This option is preferable if an enlarged window sill is planned. And, finally, the planting from solid pine, dried to 10-12% moisture, machined.

First you need to decide what material to make the casing from. The cheapest option is typesetting-adhesive, made of edged material, fastened with microthips and moisture-resistant glue. The combined window will be slightly more expensive, where the upper and side parts are made of solid pine, and the threshold is type-setting and adhesive. This option is preferable if an enlarged window sill is planned. And, finally, the planting from solid pine, dried to 10-12% moisture, machined.

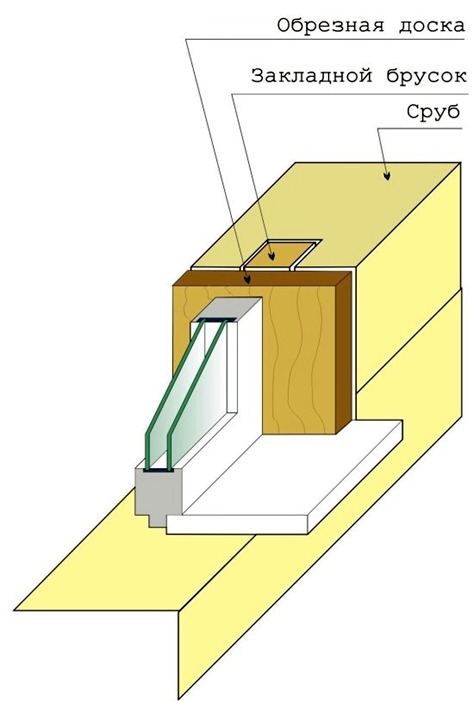

4. Cage with embedded timber

This option is the simplest, most economical and therefore deservedly popular. On the inner side of the logs of the window opening, a groove of 5 by 5 cm is cut, then a square bar is laid in it. Along this groove, the vertical movement of the log house occurs due to drying out. The junction of the bar and the logs is insulated, for example, with linen or jute fiber. Then a U-shaped structure is assembled from the boards (the actual cage), laid in the window opening and attached to the bar on the sides. The structure is attached to the crown from below. A gap of 5-8 cm should be left between the upper horizontal board of the casing and part of the wall, which is filled with insulation.

This option is the simplest, most economical and therefore deservedly popular. On the inner side of the logs of the window opening, a groove of 5 by 5 cm is cut, then a square bar is laid in it. Along this groove, the vertical movement of the log house occurs due to drying out. The junction of the bar and the logs is insulated, for example, with linen or jute fiber. Then a U-shaped structure is assembled from the boards (the actual cage), laid in the window opening and attached to the bar on the sides. The structure is attached to the crown from below. A gap of 5-8 cm should be left between the upper horizontal board of the casing and part of the wall, which is filled with insulation.

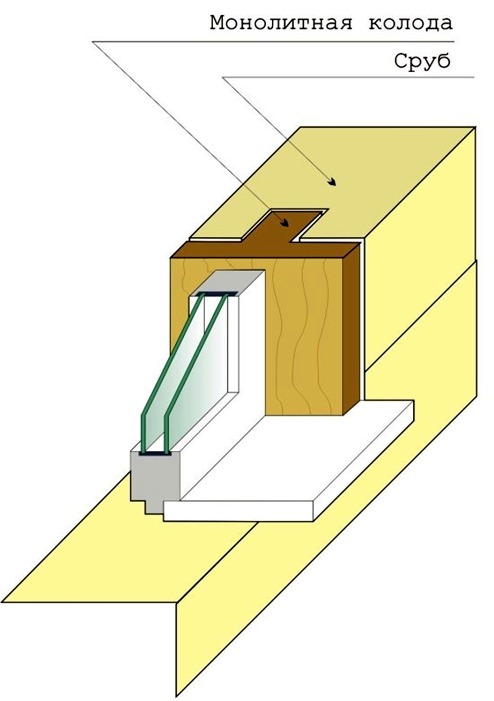

3. Siege "in the thorn"

This option is more expensive and of higher quality. For window openings using this technology, a special bar, solid or glued, with a section in the shape of the letter "T" is used. In the lateral part of the window opening, similar to the casing with a foundation bar, a groove for the spike is selected, but the installation sequence itself is slightly different. First, the prepared jambs are inserted with the T-shaped part into the side grooves laid with insulation and burst first with the lower board - a threshold or window sill, and then with the upper one - the so-called. "Top".

This option is more expensive and of higher quality. For window openings using this technology, a special bar, solid or glued, with a section in the shape of the letter "T" is used. In the lateral part of the window opening, similar to the casing with a foundation bar, a groove for the spike is selected, but the installation sequence itself is slightly different. First, the prepared jambs are inserted with the T-shaped part into the side grooves laid with insulation and burst first with the lower board - a threshold or window sill, and then with the upper one - the so-called. "Top".

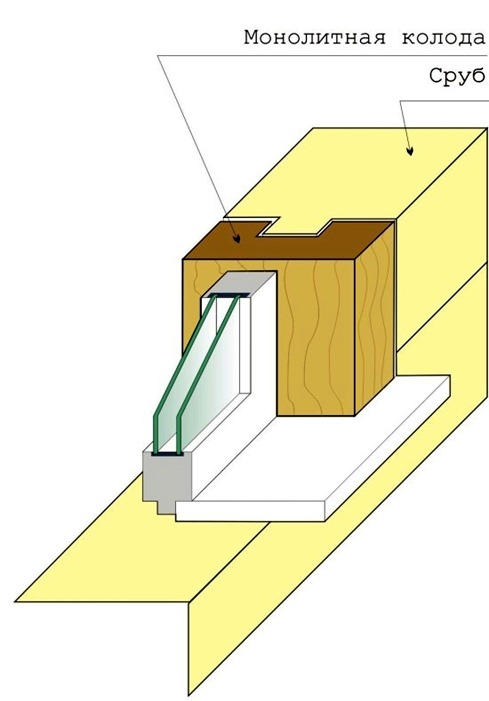

2. Siege "in the deck"

Mirroring the casing "into the thorn". This time, a 5 x 5 cm ridge is cut at the ends of the logs of the window opening. The ridge can be cut either in the middle of the end of the window opening or closer to the street (with this method, the window sills are wider). Then rolled tow is applied on top, and then prepared boards with a groove for the comb (it is necessary to leave a thermal gap).Installation takes place in the same way as the casing in the groove, that is, first, the side elements are attached to the lower rim and are expanded with the upper casing board. When shrinking, such logs will slide inside the groove without deviating from the vertical. Above, between the upper part of the window opening and the log, a gap of about 5 cm must be left for possible shrinkage.

Mirroring the casing "into the thorn". This time, a 5 x 5 cm ridge is cut at the ends of the logs of the window opening. The ridge can be cut either in the middle of the end of the window opening or closer to the street (with this method, the window sills are wider). Then rolled tow is applied on top, and then prepared boards with a groove for the comb (it is necessary to leave a thermal gap).Installation takes place in the same way as the casing in the groove, that is, first, the side elements are attached to the lower rim and are expanded with the upper casing board. When shrinking, such logs will slide inside the groove without deviating from the vertical. Above, between the upper part of the window opening and the log, a gap of about 5 cm must be left for possible shrinkage.

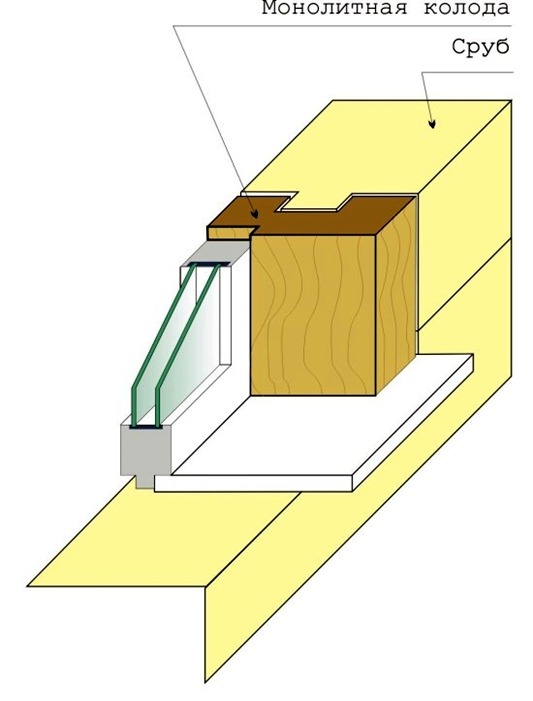

1. Siege "clean"

If the house is made of a beautiful timber or rounded logs, then it is a pity to hide such beauty. In this case, the peculiarities of the installation of plastic windows in a wooden house consist in the use of aesthetic and high-quality material for the casing elements, possibly of a special shape. From a technological point of view, this method is a modified version of a jig with a built-in bar. The jambs made in the shape of the letter "L" are installed in the window opening, attached to the embedded bars and are expanded with the lower and upper boards.

If the house is made of a beautiful timber or rounded logs, then it is a pity to hide such beauty. In this case, the peculiarities of the installation of plastic windows in a wooden house consist in the use of aesthetic and high-quality material for the casing elements, possibly of a special shape. From a technological point of view, this method is a modified version of a jig with a built-in bar. The jambs made in the shape of the letter "L" are installed in the window opening, attached to the embedded bars and are expanded with the lower and upper boards.

We examined the most popular types of casing in a wooden house, they can be made by hand according to drawings, or you can contact the professionals.